Techflow Enterprises Pvt Ltd is one of the biggest and most trusted suppliers of products like Air pollution control device, Pulse Jet Cartridge Filter, Dust Collector, Air pollution control equipment, Silo Vent filter, Fabric Filter, Dust Recovery system, Online cleaning bag filter, Off line cleaning bag filter, Bag filter, Pulse jet , Pulse jet bag filter, De-dusting system, Bag house, Cassette type filter, Reverse air cleaned bag filter, Centrifugal fans and blowers, Flue gas emission control system, Furnace fume extraction system, Welding fume extraction system and Pneumatic conveying system, Electro static precipitator (ESP) in India with worldwide exports.

Techflow has been one of the largest manufacturers of Pulse Jet Cartridge Filter since 1980. The inspiration behind designing the Cartridge Type Filter was to reduce the spacing and perform better in comparison to the Hose type bag filter. The Pulse Jet Cartridge Filter is used in medium range temperature applications where in dust particles are floating freely. Various de-dusting filtration mediums are available depending upon the application. In this system, time defined pulses or compressed air flows in opposite direction of the main airflow. Now by temporary reversal through cleaning-blast via ventury, the cartridge surface is cleaned.

Discover more| Pulse Jet Cartridge Filter |

|---|

In Pulse Jet Cartridge Filter system, the contaminated air flows through the wherein the cartridges retain the dust particles, ensuring that only clean and contamination free air remains in the environment. The Cartridge type Pulse Jet Filters (C-TPJF) have an advantage of compact design and lower space acquisition. This is the prime reason why these systems are heavily used in Sand Blasting, Shot Blasting, Mineral Grinding, Pigments & Chemicals, Polymers, Ceramics, Grinding & Polishing, Abrasive Manufacturing, Food Processing, Spices, Pneumatic conveying systems, Powder coating, Engineering workshops, Welding & Cutting, Cattle Feed & Grain Handling and many more. Techflow offers a wide variety of Pulse Jet Cartridge Filter having a range between 1000 CuM/Hr to 1,00,000 CuM/Hr. These Cartridge Filters are available with different spares and options like surface filtration technology, discharge device and variety of fabrics suitable for different applications. |

1. OPERATING PRINCIPAL (ON-LINE CLEANED)

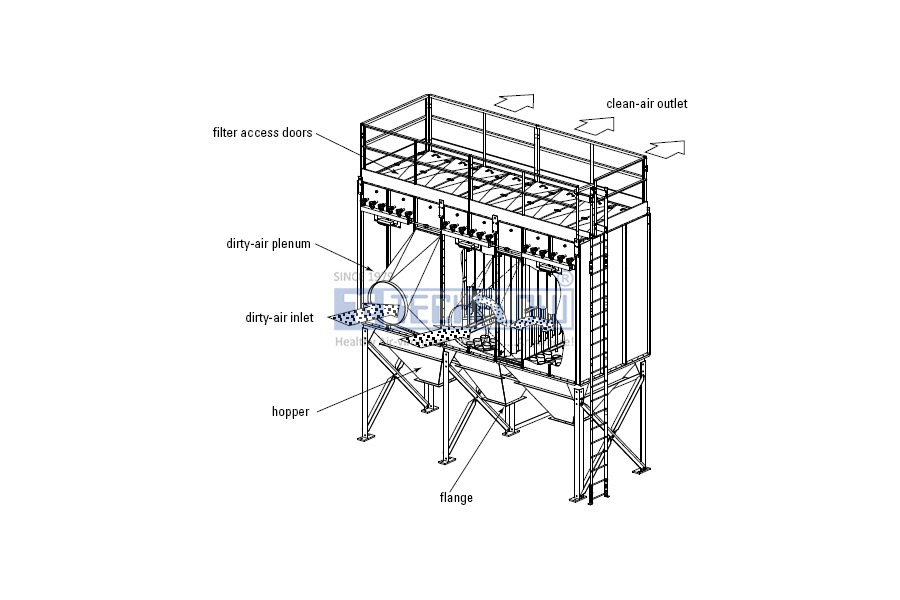

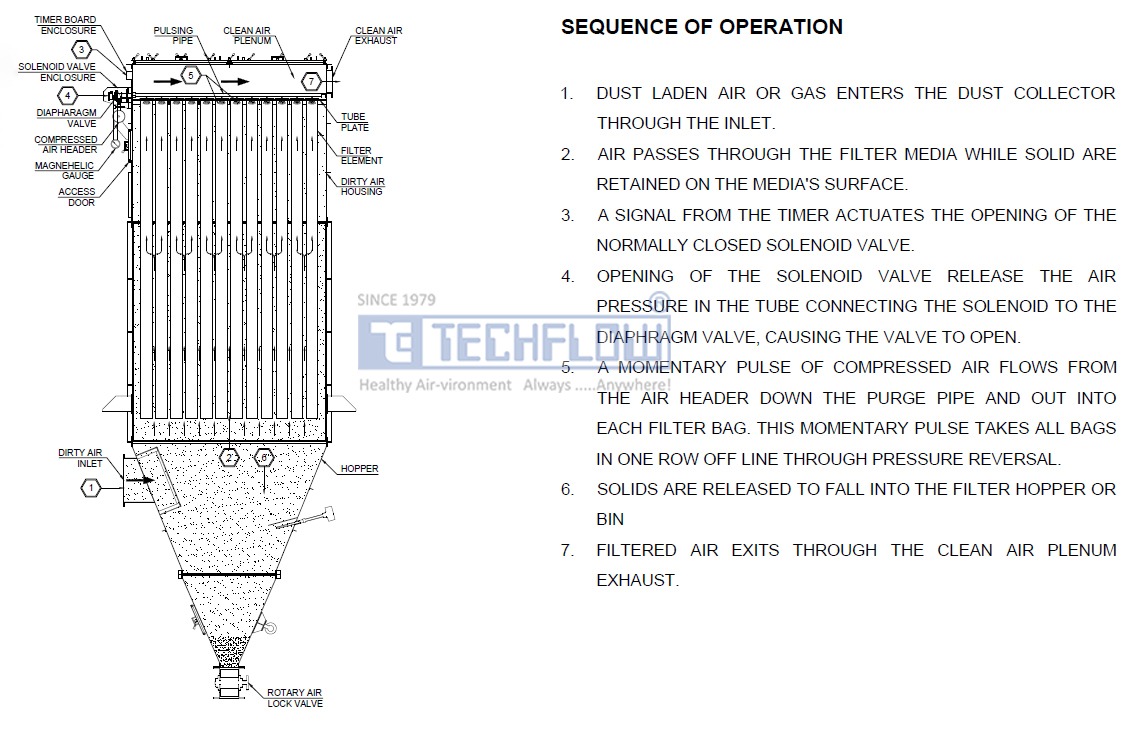

Dust laden air enters the hopper where heavier particles drop out of the air stream. The lighter particles are trapped in the air stream and rise into the filter bags. As the air passes through the filter bags, the dust particles are collected on the outside surface of the filter bags and the cleaned air is exhausted out through the collector. At precise intervals, jets of compressed high-pressure air pass through venturis thru pulse valve and blow pipes, inducing a strong flow of secondary air, briefly reversing the airflow through the bags. This produces an internal shock wave which travels down the length of the bag, causing the bag to pressurize and flex outwards. This allows reversed airflow to dislodge accumulated dust on the outside of the bag where it falls down into a collection hopper. With this method of cleaning, airflow through a row of bags is reversed for only a fraction of a second, resulting in steady state airflow conditions throughout the dust collector. The cleaning operation is controlled by an easily adjusted solid state timer. A Differential Pressure gauge permits optimum regulation of the timer. Pulse durations and pulse intervals can be simply and accurately set at the timer to minimize compressed air consumption.

2. General Function of Pulse Jet Cartridge Filter (C-TPJF) :

For clean venting of flue gas emissions from remove particulate matter & control of SPM level Unit has been designed & manufactured as per joint prior discussions & technical concurrence on parameters like Dust loading, Air to cloth ratio, Can velocity, Existing & new bag cage sizes, Inlets/ outlets, Heaters, Control system etc.